Post 04 - Power Plant Equipments and its Functions

FUNCTIONAL DESCRIPTION

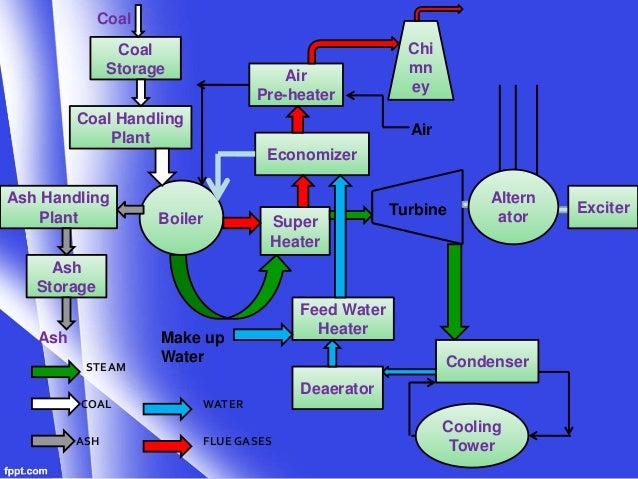

Power Plant

In

Thermal Power Station fuel burns & use the resultant to make the steam,

which derives the turbo generator. The Fuel i.e. coal is burnt in pulverized

from. The pressure energy of the steam produce is converted into mechanical

energy with the help of turbine. The mechanical energy is fed to the generator

where the magnet rotate inside a set of stator winding & thus electricity

is produced in India 65% of total power is generated by thermal power stations.

To understand the working of the Thermal Power Station plant, we can divide the

whole process into following parts.

1. COAL

FLOW

In

coal fired plants, raw material are air & water in PTPS, coal is

transported through Railway wagons from M/s Coal India & is kept reserved

on a buffer stock. The brought out to the station is unloaded with the help of

wagon tippler. After unloading, the coal is sent to crusher house with the help

of conveyor belts. The coal which is now reduced to very small pieces is sent

to the coal bunkers with the help of conveyor belt. The raw coal is fed to coal mills through raw

coal feeders raw coal feeders basically regulate raw coal to pulverized coal

pipes. A position of the primary air is heated utilizing the heat of the fuel

gases & then mixed with the cold air as per requirement by the pulverized

coal. Normally the temperature is maintained at 60 to 70 degrees. The coal is

now burnt in the furnace using oil in the beginning showered through the

nozzles at different elevations in the furnace. To provide air for combustion,

the heat of the flue gases also heat it the heat produced due to combustion is

utilized for the conversion of water into steam. This water is stored in the

boiler drum. There are two sets of pipes attached to the drum, one called riser

& other known as down corner through which the water comes to the ring

header & steam moves up due to the density difference of water & steam.

Its steam is super heated using super heaters & meanwhile the flue gases

are through out in the atmosphere through chimney.

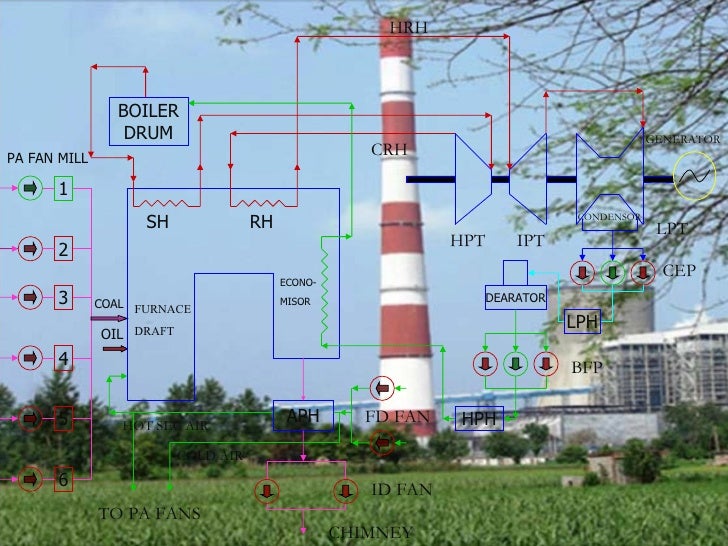

2. STEAM FLOW

The

super heated steam is sent to the turbine through pipelines there are three

turbines in the units, using this steam at different temperature &

pressures. After passing through high pressure turbine the steam is send to the

reheater for risingthe temperature of the steam. After reheating the steam is

sent to the intermediate pressure turbine through reheated line. Here it losses

most of its temperature & pressure & finally sent to low pressure

turbine. The uses of three different turbines help in increasing the efficiency

of the plant. The turbine in turn connecting with a generator produces

electricity. Then this electricity is stepped up to grid voltage with the help of step

up transformer & supplied to various sub-stations grids.

Meanwhile,

the steam through low pressure (L.P.) Turbine is condensed and the condensed

water is stored in hot well.

3. WATER FLOW

The

condensed water is extracted from the hot well through condensate extraction

pumps & sent to the boiler drum with the help of BOILER FEED PUMP (B.F.P.)

before passing through low pressure heater and dearater. While loss in water is

make up from C.S. Tank, which have D.M. Moor in it. The C.S. Tank is directly

connected to hot well.

The

water used in condenser is sent to cooling tower for cooling. After cooling

this water is again sent to condenser with the help of circulating water pump.

The loss is making from raw water pump house through clarifier pump house.

|

| RO PLANT |

COMPONENTS

DESCRIPTION

1. WAGON TIPPLER:

It

is the machine which is used to tip the coal from the wagon. The coal tipped is

directly feed to conveyor belt. Its capacity is 12 wagon per hour.

2. CRUSHER:

3. COAL MILLS:

4. FURNACE:

5. BOILER DRUM:

6. ELECTROSTATIC PRECIPITATOR:

In

this we have electrodes which attract fly ash and extract it from flue gases so

that it cannot enter atmosphere.

7. CHIMENY:

8. TURBINE:

Turbine

is the part which revolves due to steam pressure. It is of three types.

a) High

pressure turbine.

b) Intermediate

pressure turbine.

c) Low

pressure turbine.

9. TURBO GENERATOR:

It

is the main machine which produces electricity .It is (H2O)

water and H2 (Hydrogen) gas cooled therefore it is contained in

cylindrical chamber.

10. CONDENSER:

It condenses steam coming from low pressure turbine (L.P.T.)

to hot water. By removing air and other non-condensable gases from steam while

passing through them.

11. COOLING WATER (C.W.) PUMP:

12. COOLING TOWER:

It

is used to coal the water its height is near about 143.5 mtrs. The hot water is

led to the tower top and falls down through the tower and is broken into small

particles while passing over the baffing devices. Air enters the tower from the bottom and flow

upwards. The air vaporizes a small percentage of water, thereby cooling water

falls down into tank below the tower from where it is pumped to the condenser

and cycle is repeated.

13. RAW WATER PUMP HOUSE:

14. CLARIFIER PUMP HOUSE:

The

water from raw is clear at clarifier by putting alum in it & filtering it

& then supplied to the condenser.

15. CONDENSATE EXTRACTION PUMP:

C.E.P.

pump is used to extract the condense water from the hot well and supply to the

deaerator after passing through L.P. heater & Economizer, so that high

pressure steam in the cylinder can be created.

16. LOW PRESSURE HEATER:

It

is used to increase the temperature of water, in this way efficiency of system

increases.

17. DEAREATER:

It

is used to remove air from water which is entrapped in the water molecules. It

is very important part because the entrapped air effect air drum badly.

18. BOILER FEED PUM (B.F.P.):

19. HIGH PRESSURE HEATER (H.P.):

20. ECONOMISER:

In

this flue gases exchange heat to the water to increase system efficiency, causes saving in fuel consumption

(5 to 10%). Economizer tubes are made up of steel either smooth or covered with

fins to increase the heat transfer surface area.

Comments

Post a Comment